Given the external pressures of recent years, companies that have invested more heavily in digital processes are generally seeing more success. Logistics depends, more than many other industries, on a wide range of variables, from weather conditions to immigrant experiences. The more of those variables the company understands and controls, the more reliable and predictable deliveries will be. DigitalMara has put together a list of tips for simplifying logistics processes and making the digitalization process smoother.

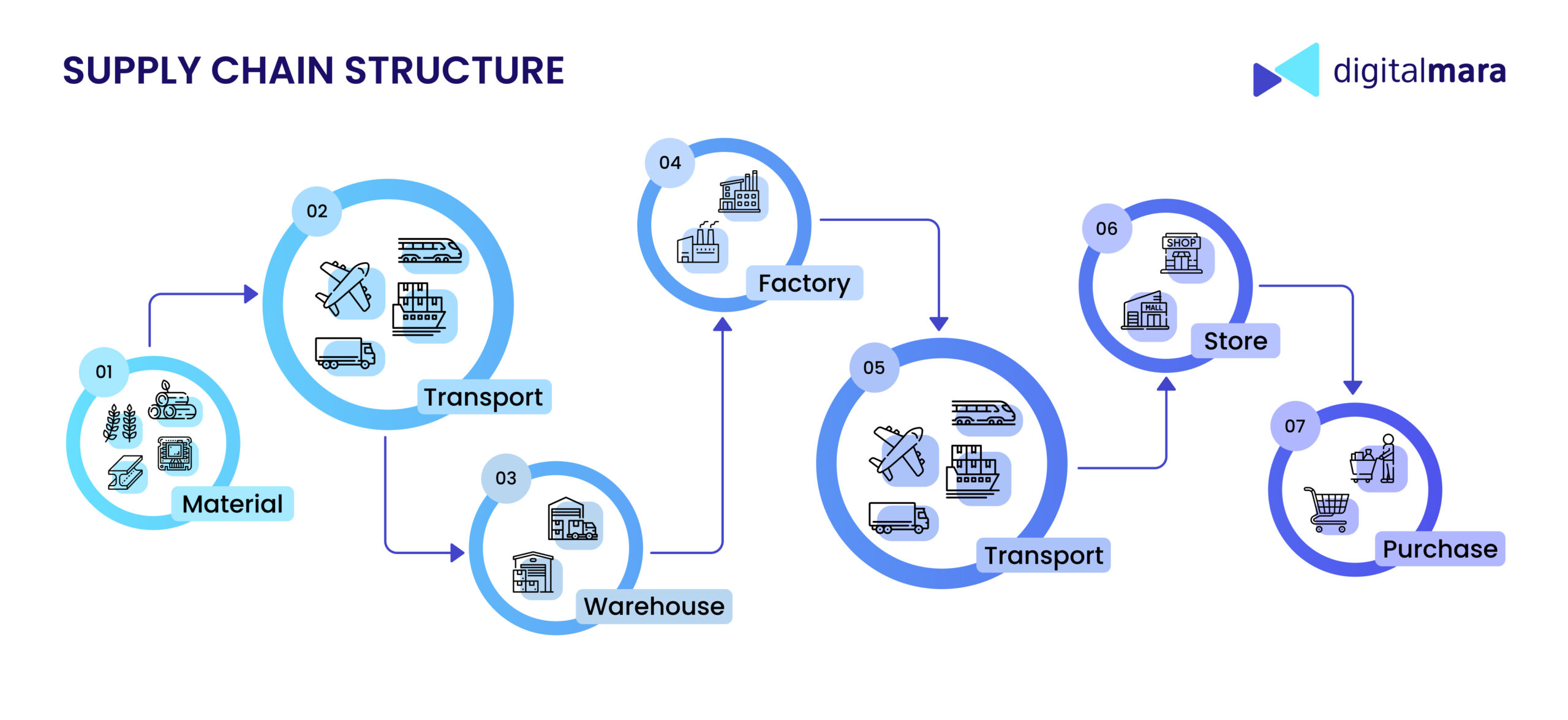

Logistics refers to a process of efficient planning, bookkeeping, management, storage and moving of items within the B2B, B2C, or C2C supply chain. This includes various modes of transportation: trucks, trains, ships, and planes. Building a route for each type of transport has its own peculiarities and variables, including different speed, time and costs. The basic requirement in any supply chain is that it move goods in a timely and cost-effective manner, with minimal errors. Other important factors include sustainability efforts, reducing the carbon footprint and avoiding negative social impact.

Faced with a wide range of challenges during the global pandemic, the field of logistics suffered financial losses. In 2022, Statista reported a recovery phase with a market size of $10.41 trillion, predicting a slight growth in 2023 of approximately 3%. At this point, new technology solutions could help stabilize and strengthen logistics operations. Companies deploying them can improve efficiency through automation, optimize their operations, reduce costs, gain real-time visibility, make more informed decisions, enhance safety and much more.

Logistics software features

Logistics providers serve manufacturers, retailers, e-commerce and other industries. Some own the full range of infrastructure, including transport, warehouses and software, while others specialize in one or two parts. Some companies prefer to have their own logistics departments and organize the whole supply chain themselves.

Typically, companies develop their custom software in-house or externally, or use out-of-the-box solutions for logistics presented in the market. The term software solutions for logistics refers to the various digital tools and technologies used to manage and optimize various aspects of the logistics process:

- Order management for tracking orders from start to end and generating shipping labels, invoices, and other essential documents.

- Inventory management allows users to track inventory levels and assets, set reorder points, and generate reports.

- Route planning and optimization generates the most efficient routes, considering factors such as traffic, distance, and delivery windows.

- Real-time tracking enables users to track the location of their shipments at any given time.

- Warehouse management involves tracking inventory levels, managing storage locations, and generating reports.

- Analytics and reporting enable users to analyze their logistics operations and make data-driven decisions.

- Customer management: for tracking customer orders, managing customer accounts, and generating reports.

- Security features to protect sensitive data such as customer information and financial data. It includes user authentication, data encryption, and regular backups.

- Integrations with other systems like accounting software, e-commerce platforms, and CRM systems.

- Accessibility on mobile devices to manage logistics operations on the go.

One of the major challenges in logistics software development is ensuring compatibility with existing systems, technologies and a wide range of devices such as barcode scanners, RFID readers, GPS devices, electronic logging devices (ELDs), temperature monitoring devices, handheld computers, telematics and temperature monitoring devices, and others. All these components, forming complex networks, may be developed by different vendors and operate on different platforms, making it difficult to integrate them seamlessly.

Logistics requires handling large amounts of data. The problem is that the data may come from different sources, in different formats. Therefore, centralized data management is crucial. All information should be collected, systematized, converted to another format if necessary, and moved between systems smoothly. Users should be able to read it, analyze it and take actions based on this knowledge.

Table – Roles and actions in a logistics software system

| Software block | Role | Action |

| Inventory Management System Process orders, manage and control the inventory levels of items, track their movement through various points of the supply chain. |

Customer | Placing order. |

| Office worker | Planning, optimization and forecasting. Placing order. | |

| Track & Trace Track the current status of a shipment and keep updates, access to the full history of the shipment, estimated time of arrival (ETA). |

Customer | Tracking shipment status. |

| Office worker | Tracking shipment status. | |

| Warehouse Management System Track inventory levels, space utilization, process orders and move items within a warehouse. |

Warehouse worker | Using RFID readers and barcode scanners for data entry and tracking. |

| Office worker | Managing warehouse operations. | |

| Transportation Management System Process orders, schedule deliveries, plan routes, update driver rosters. |

Driver | Using GPS devices and Electronic Logging Devices for data entry and tracking. |

| Office worker | Building and adjusting routes. | |

| Finance System Manage financial transactions and processes related to the movement of items across the supply chain. |

Customer | Paying for delivery. |

| Office worker | Placing a request for payment. | |

| Accountant | Managing finance flows, recording transactions, preparing invoices, reporting. | |

| Analytics System Collect, process and analyze data from back-office data, data generated by interactions, by various types of sensors, by clients and other companies. |

Data analyst | Identify patterns, trends, and anomalies in the data for better decision-making. |

Technologies to develop logistics systems

Cloud technologies

Using cloud technologies in logistics makes it possible to manage and optimize operations, to automate and streamline processes, as well as to make them more efficient. Cloud-based logistics software offers benefits such as real-time data access, scalability, and cost savings compared to traditional on-premises software. In addition, it allows for better collaboration between different parties in the supply chain and visibility across inventory levels, shipments, and warehouse activities.

Cloud applications can be used for inventory management, transportation management, and warehouse management, making all operations more accurate and efficient, reducing risks and errors, lowering time and cost for each operation, and allowing better interaction between systems, with continuous and smooth data flows. Also, cloud solutions provide for a wider range of functions, for example demand forecasting, automated inventory tracking, automated replenishment, carrier selection, freight auditing, automated shipment tracking, order management, automated picking and packing, and much more.

Artificial intelligence

AI has solidly entered the world of logistics, changing the ways companies manage and optimize their supply chains. It can analyze large amounts of data from various sources such as IoT devices and weather forecasts, automate processes and make predictions, bringing more visibility and transparency. All of this helps companies make better decisions, optimize processes, and improve overall efficiency.

- Planning – analysis of historical data and predicting future demand to plan operations accordingly; routes optimization based on wide range of factors, reducing delivery times and costs; tracking shipments in real-time to proactively address any issues that arise during transit; identifying potential risks in the supply chain, such as delays or disruptions, to mitigate them in efficient way.

- Warehouse automation – robots that can sort, pick, pack, organize and transport inventory; analysis of product images to identify defects, improving quality control processes and reducing errors; data analysis on inventory levels and demand patterns to optimize inventory placement, reduce waste, and improve order fulfillment.

IoT

The Internet of Things is another technology useful for optimizing and improving logistics processes. IoT devices include radio-frequency identification (RFID) tags, eSIM and GPS, and other sensors. For shipment-tracking and monitoring purposes, they can track location or monitor temperature, humidity and other real-time conditions. AI algorithms can be used to process this data to help with route management and improve security, predict issues and mitigate them.

For inventory management purposes, RFID tags and IoT sensors can be placed on items in warehouses to track location and inventory levels in real time. This data makes it possible to improve forecasting and optimize inventory levels. IoT devices used in vehicles can provide data about real-time vehicle location, vehicle status and speed and also manage trailer or truck weight. Companies have the opportunity to optimize routes and scheduling, reduce downtime and improve transport performance, control their drivers, and reduce fuel costs.

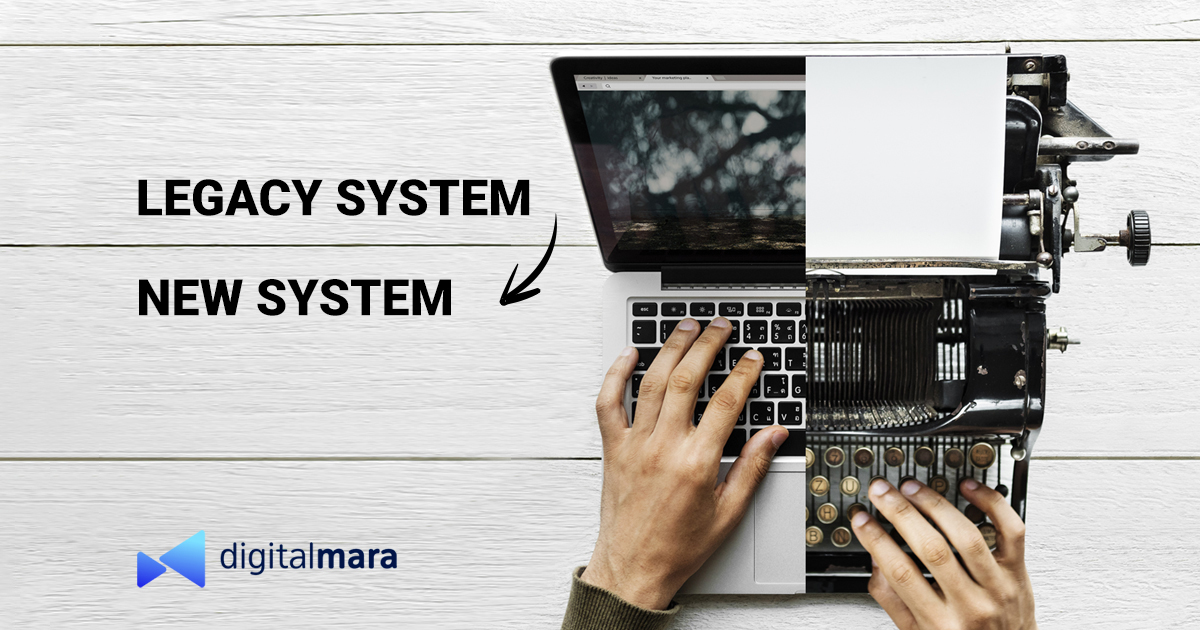

Legacy software in logistics

Transportation and supply chains are influenced by a variety of internal and external factors. IT systems serving them should be flexible enough to adapt to these challenges. However, the old methods are still with us: orders tracked using a spreadsheet, old proprietary data collection systems, a clipboard with inventory data, delivery routes planned with spreadsheets, and outdated transportation management systems, with indecipherable and ambiguous product and article codes.

It’s obvious that retaining these legacy systems has a negative impact. They are inefficient, slow and error-prone, leading to increased costs, delays and other losses. Legacy systems also have higher security risks, being vulnerable to cyber-attacks and other threats. In addition, they are incompatible with new technologies, components and software, which limits data exchange and collaboration. Modernization enhances efficiency and provides better visibility and control over the supply chain.

Compliance for software in logistics

There are numerous compliance regulations in logistics related to safety, security, environment, hours-of-service and international trade laws. Technology solutions can help. For example, GPS tracking and telematics systems can be used to ensure drivers are operating within legal speed limits, prevent accidents and maintain vehicles. Electronic logging devices (ELDs) control the number of hours commercial drivers can operate a vehicle in a day. Technology can be used to identify potential risks and vulnerabilities in the supply chain, to mitigate them. And software solutions can help companies track and report on their environmental impact, such as carbon emissions from transportation.

Final words

A logistics system is a highly complicated one, with multiple components. Each has its own functionality but works closely with the rest. Therefore, system modernization or development from scratch is a multi-stage process that involves considering the business model, defining the technology stack and ensuring a pool of digital talents. It is important to set tasks properly, divide them into iterations, and compile documentation with a detailed description of how the system works.

To achieve those goals, it’s important to have a reliable software development partner. DigitalMara has vast experience working with big and complex systems and solving the tasks of system modernization and custom software development.