Consulting and Training for fleXality - Climate tech Startup based on Machine Learning

DigitalMara conducted training sessions for the client’s internal tech team. fleXality developed a proprietary algorithm based on Machine Learning and needed additional knowledge on how to assemble all components into a unified system and deploy it into the cloud.

About the client

fleXality GmbH

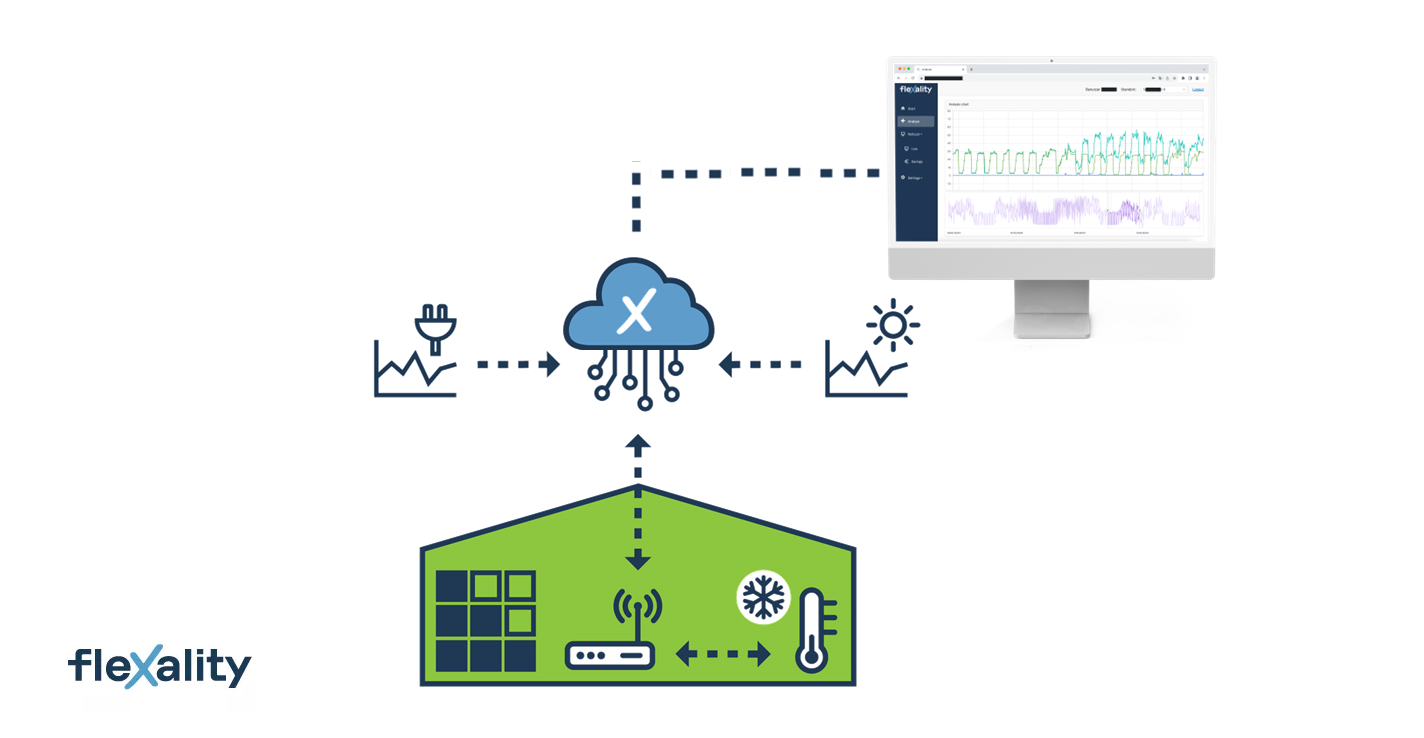

fleXality, a German climate tech startup, provides data-driven solutions designed to optimize energy consumption in cold storage facilities. The company aims to reduce both energy costs and CO2 emissions by strategically shifting energy use for refrigeration to periods when electricity prices are lower and renewable energy availability is higher. To achieve this, fleXality developed a proprietary Machine Learning (ML) algorithm. This algorithm underpins a system that collects and analyzes data, forecasts energy demand for refrigeration, and offers actionable recommendations for cost optimization based on physical, operational, and process parameters.

Challenge

The client sought to review their internal processes and obtain expert consultancy from specialists familiar with the unique demands of such projects. Meanwhile, fleXality aimed to expand their expertise in assembling and deploying a complete system from individual components into a live production environment.

Approach

We assessed the technical aspects of the tasks to be addressed and developed a comprehensive training plan. Over the course of the month, our Senior MLOps engineer led several training sessions via video conference. For each session, we prepared a list of key questions and answers in advance. Additionally, our engineer promptly addressed any spontaneous questions that arose during the sessions.

During the sessions, we covered the following topics:

- Discussed building ML models and pipelines in both the cloud and local networks.

- Created examples of pipelines for model deployment.

- Explored improvements for the architecture of production pipelines.

- Conducted deep dives into the nuances of MLflow.

Results

As a result of the training, the client enhanced their ability to build pipelines, optimize their ML architecture, and improve the interaction between system components. They are now equipped to deploy the system into production using cutting-edge processes.

Get case study as PDF

Thank you

The PDF has been sent to you via email. If you have any questions, please don't hesitate to reach out to us.